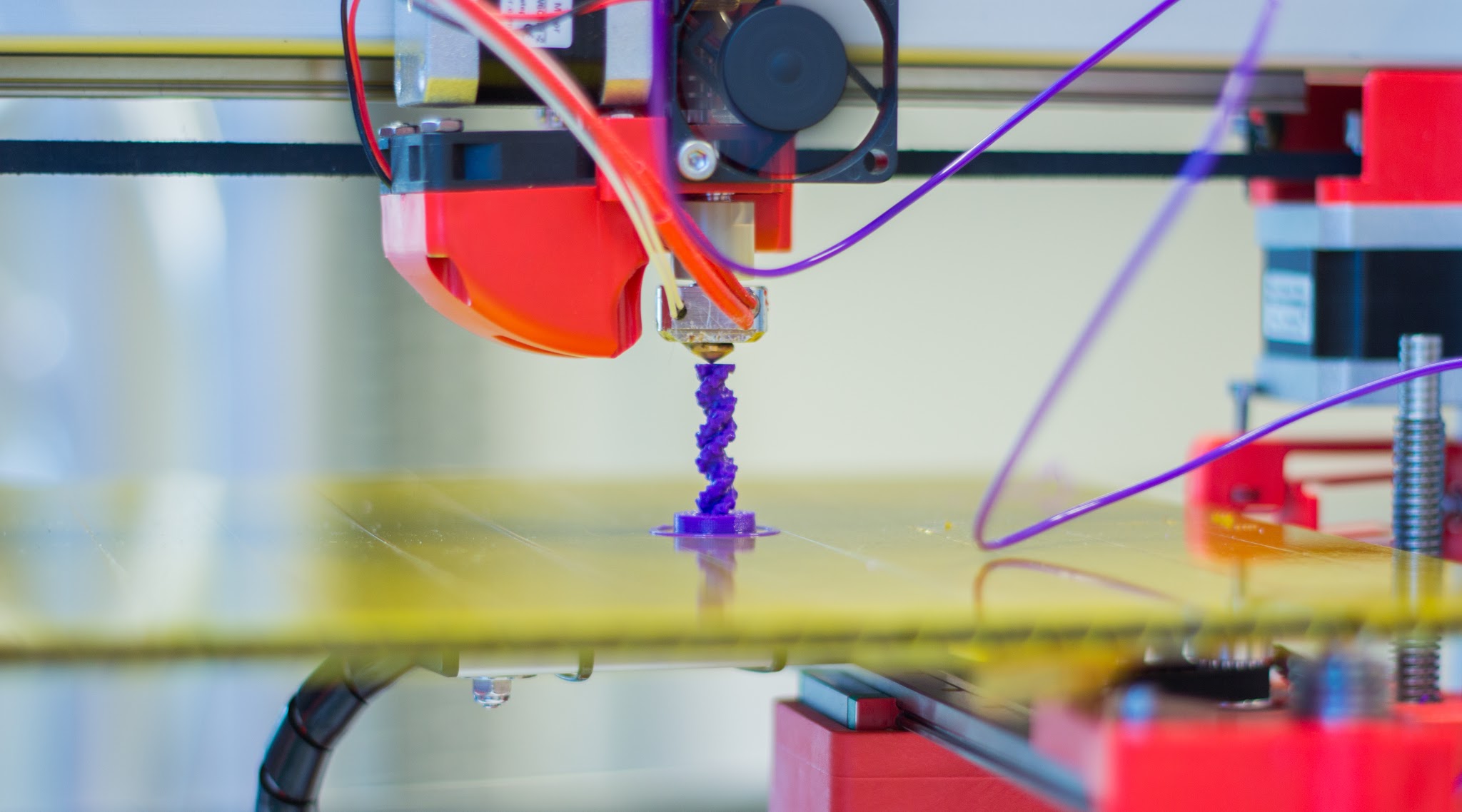

Aircraft industry data was used to complete a case study of the life-cycle environmental effects of using 3-D printing for select metal aircraft parts, a technique that is already being adopted by the industry.

3-D printing the lighter and higher performance parts could significantly reduce both manufacturing waste and the weight of the airplane, thus saving fuel, money and decreasing carbon emissions.

“The airline industry is an early adopter of 3-D printing,” said lead author Eric Masanet, professor in materials and manufacturing at Northwestern University.

“The main driver is that aircraft require specialized lightweight metal alloys that can be very costly to process,” Masanet said.

The conventional manufacturing methods tend to be inefficient and wasteful.

3-D printing, on the other hand, requires far less raw material inputs and can further produce parts that minimise weight through better design.

If 3-D components evaluated in the case study are used to their full potential, it would greatly benefit the environment in more than one way.

The team estimated that airplane fuel consumption could be reduced by as much as 6.4 percent, reducing both fossil fuel dependency and greenhouse gas emissions.

Their life-cycle analysis found that manufacturing 3-D printed components uses as little as one-third to one-half of the energy currently used in conventional methods.

“If we can accelerate the necessary process improvements, then we can start reaping these savings sooner. Maybe then, we can start seeing savings 10 years earlier than if we just let the technology progress at its regular rate,” Masanet added.

The study was published in the Journal of Cleaner Production.